0.00 ₽

Оформить заказУниверсальный однофазный моноблочный сварочный аппарат ФОРСАЖ-200ПА, использующий сварочную проволоку диаметром от 0,6 до 1,0 мм, предназначен для:

- полуавтоматической сварки (режим MIG/MAG) деталей из углеродистых и легированных сталей

- в среде инертных/активных газов, их смесей;

- в среде без газа самозащитными порошковыми проволоками.

- ручной электродуговой сварки (режим ММА) штучными плавкими электродами любой марки диаметром от 1,6 до 5,0 мм при дуге, образованной постоянным током, регулируемым в диапазоне от 15 до 200 А.

Оригинальные схемно-технические решения, реализованные на элементной базе от лучших зарубежных производителей, применение встроенного 2-х роликового механизма подачи проволоки «COOPTIM» (Венгрия) под катушку диаметром 200 мм обеспечивают высокое качество сварки.

Сварочный полуавтомат инверторного типа ФОРСАЖ-200ПА имеет возможность настройки параметров сварки под конкретную деталь с сохранением их в памяти аппарата. Это позволяет обеспечить высокую производительность сварочных работ и хорошее качество конечного результата, а также значительно упростить сам процесс сварки. Аттестуется по РД 03-614-03 (НАКС).

Аппарат обеспечивает стабильные сварочные свойства при снижении напряжения питания сети до 140 В при работе с электродами диаметром до 3,0 мм и сварочной проволокой 0,6 мм.

Благодаря автоматическому управлению работой вентилятора значительно снижаются объемы энергопотребления и попадания пыли внутрь сварочного аппарата.

Основные преимущества сварочного полуавтомата инверторного типа ФОРСАЖ-200ПА:

- Универсальность

- Высококачественное формирование шва

- Возможность осуществления продолжительного цикла работ

- Электронная стабилизация выходных параметров

- Работоспособность при снижении напряжения питания до 140 В

- Малое энергопотребление

- Защита от пыли за счет эффективного управления работой вентилятора

Функциональные возможности сварочного полуавтомата ФОРСАЖ-200ПА:

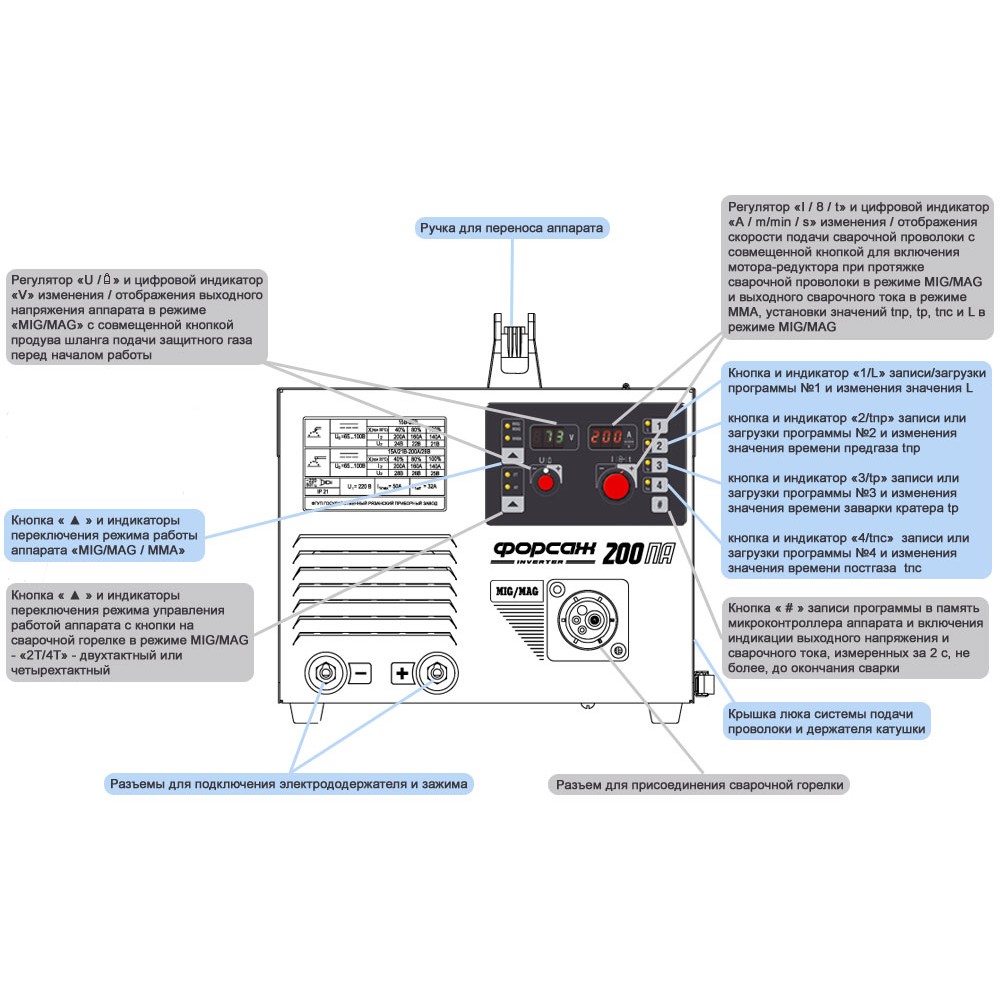

- Установка и контроль сварочного тока и напряжения по цифровым индикаторам

- Режимы управления от горелки - двухтактный и четырехтактный

- Регулировка времени продувки газа до и после сварки, растяжки дуги в режиме MIG/MAG

- Регулировка скорости нарастания тока К.З. (электронная индуктивность) в режиме MIG/MAG

- Изменяемая полярность

- Хранение в памяти 4-х пользовательских программ в режиме MIG/MAG

- Функции ARC FORCE, HOTSTART, ANTISTICK в режиме ММА

- Запись в память фактических значений выходного тока и напряжения

- Автоматическое сохранение настроек сварочного инвертора после 1 мин устойчивой работы

- Автоматическое отключение при перепадах напряжения сети

- Автоматическая защита при перегреве и при аварии

- Работа от передвижных электростанций мощностью не менее 14 кВ·А

- Возможность TIG-сварки при использовании специальной горелки