0.00 ₽

Оформить заказМногофункциональный сварочный инвертор ФОРСАЖ-315АД предназначен для аргонодуговой сварки постоянным током деталей и материалов из стали и медных сплавов и ручной электродуговой сварки штучными электродами диаметром 1,6 – 5,0 мм.

Аргонодуговая сварка (режим TIG) осуществляется неплавящимися вольфрамовыми электродами в среде инертных газов (аргон и его смеси с гелием и другими газами) с применением присадочной проволоки при дуге, образованной постоянным током, регулируемым в пределах от 10 до 315 А. Наличие у инвертора импульсного режима позволяет регулировать тепловложения и управлять скоростью кристаллизации шва, обеспечивая высочайшее качество сварки.

Ручная дуговая сварка (ММА) выполняется штучными плавкими электродами любой марки диаметром от 1,6 до 5,0 мм при дуге, образованной постоянным током, регулируемым в пределах от 20 до 315 А. Регулируемый импульсный режим облегчает осуществление сварки в различных пространственных положениях (вертикальные и потолочные швы), сварку деталей малой толщины.

Сварочный инвертор ФОРСАЖ-315АД позволяет устанавливать параметры сварки под конкретный материал с последующим их сохранением в памяти аппарата. Это обеспечивает простоту использования инвертора, высокую производительность и качественный результат сварки.

Микропроцессорное управление и оригинальные схемно-технические решения позволили добиться высокого качества шва в любом пространственном положении, стабильности сварочного процесса и обеспечить широкий набор функциональных возможностей.

Основные преимущества сварочного инвертора ФОРСАЖ-315АД:

- Возможность бесконтактного и контактного поджига дуги

- Электронная стабилизация тока сварочной дуги

- Высокое качество сварки при применении электродов с различным типом покрытия

- Малое энергопотребление

- Компактность

- Защита от пыли за счет эффективного управления работой вентилятора

- Функциональные возможности сварочного инвертора ФОРСАЖ-315АД:

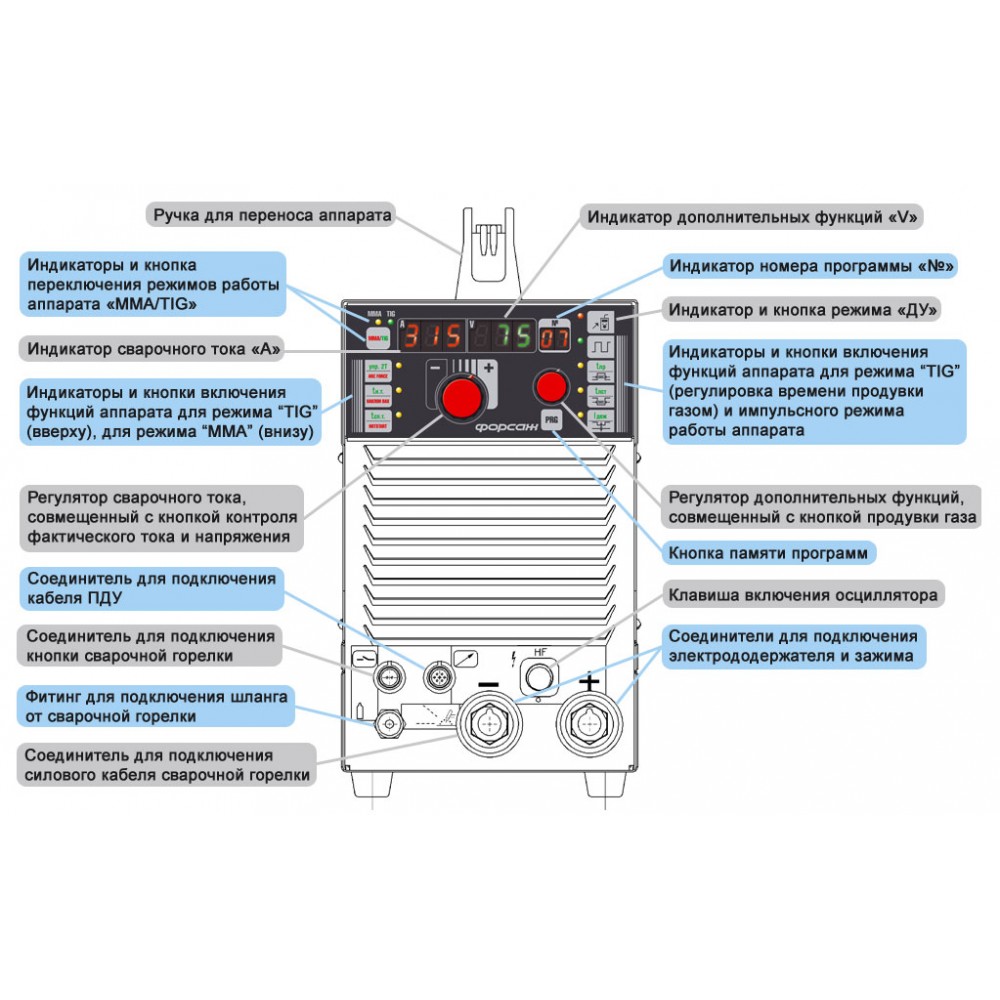

- Установка и контроль сварочного тока и напряжения по цифровым индикаторам

- Регулировка времени нарастания и спада сварочного тока в режиме TIG

- Регулировка времени подачи защитного газа перед и после сварки в режиме TIG

- Регулируемый импульсный режим

- Функция PILOT ARC (дежурная дуга)

- Регулировка наклона выходной вольтамперной характеристики в режиме ММА

- Регулируемые функции НОТ START, ARC FORCE в режиме ММА

- Функция ANTISTICK в режиме ММА

- Автоматическое отключение при перепадах напряжения сети

- Автоматическая защита при перегреве аппарата и при аварии

- Дистанционное управление

- Автоматическое сохранение настроек сварочного инвертора после 1 мин устойчивой работы

- Память на 20 пользовательских программ в режиме TIG и 7 программ в режиме ММА

- Питание от передвижных электростанций мощностью не менее 20 кВ·А